Harima Releases Water-based Barrier Coating Agents for Paper

Oct 9, 2025

Harima is glad to announce the release of water-based barrier coating agents formulated with a high biomass content, and which give paper superior resistance to water, oil, heat, and moisture.

With growing global interest for more ecological products and technologies, plastic materials are gradually being replaced with paper. The packaging sector is also seeing an increase in biomass-based materials, from among which trees present the additional advantage of having absorbed carbon dioxide during their lifecycle and are also renewable, which makes them truly sustainable. However, given that paper easily absorbs water and oil, the vast majority of food-contact items such as paper cups and cartons use laminated films to inhibit absorption.

On the other hand, laminated films have the disadvantage of being petroleum-based and not easily recyclable, which has made it necessary to look into more sustainable options. Barrier coatings form a protective layer on the paper that repels various elements, enhancing the paper's functionality and enlarging its scope of application. This contributes significantly to the reduction of plastics, of which packaging materials account for nearly 70%, and is an excellent alternative to lamination, a trend on the rise in more environmentally conscious markets such as Europe.

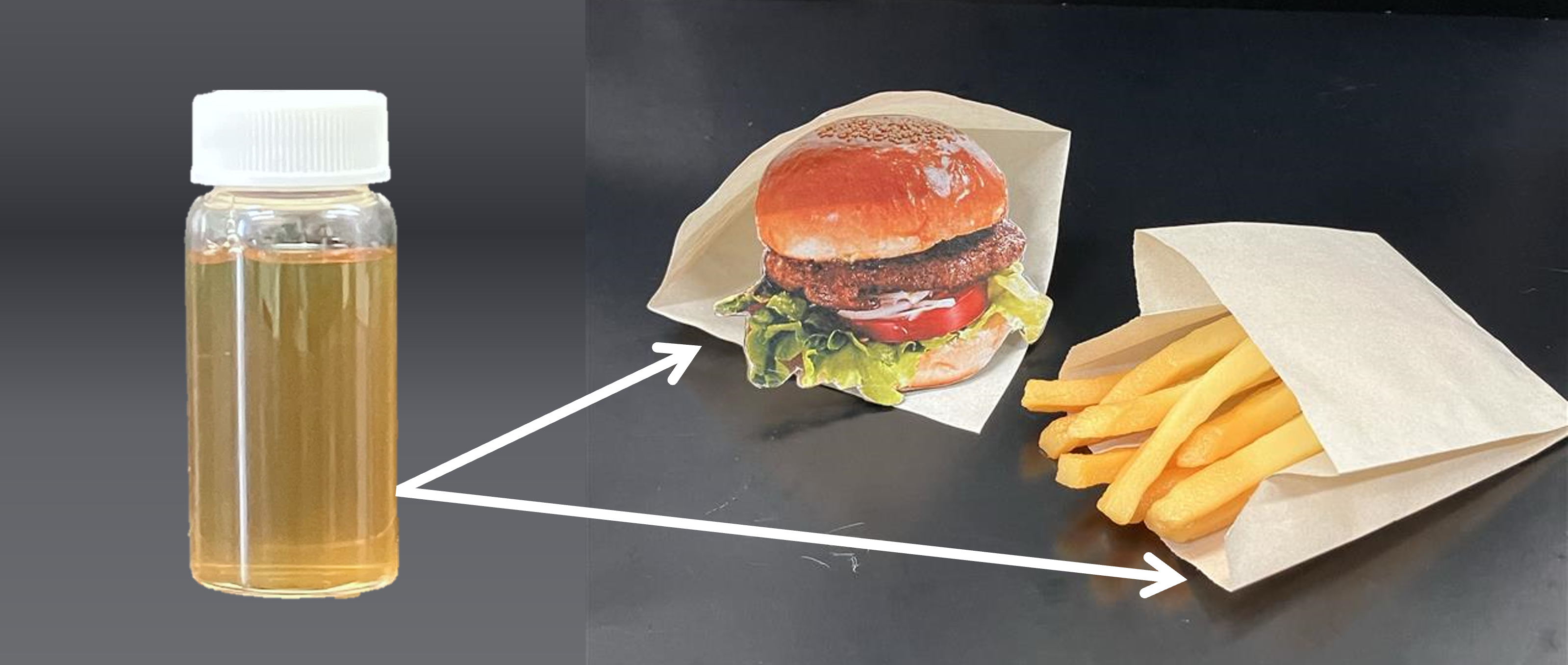

Example of food contact materials that use Harima's coating agents

Harima's newly developed barrier coating agents have a high pine-based biomass content of up to 85%, which boosts both their sustainability and capabilities. In addition, they are water-borne and solvent-free, which makes them safer and mitigates environmental impact. They are also compliant with the following international certifications, and thus can be employed as food contact materials (FCMs) with a wide range of products around the world: US's FDA, Germany's BfR, Swiss Ordinance*1, EU Plastic Regulation*2, and Japan's Positive List System*3.

Paper materials used in lieu of plastic films are progressively expanding, with the Japanese market estimated to reach approx. 3.5 billion Japanese yen by 2027, an increase of 75% compared to 2023. Harima's water-based coating agents are successfully responding to this demand through exceptional quality, opening new possibilities in the industry.

■Reference Data

*1 Swiss Ordinance §817.023.21

This regulation is the world's first to cover printing inks used in food packaging, and establishes the specific requirements for the manufacturing, labeling, and marketing of food contact materials in Switzerland, with the goal of protecting consumer health. Its strict migration limits have become a reference point across the world as a de facto standard.

*2 EU Plastic Regulation No.10/2011

This regulation defines the safety requirements for plastic materials and articles intended to come into contact with food within the European Union. It sets specific limits on how much any substance used in plastic can transfer to food, establishes rules for the manufacturing and marketing of these articles, and requires that only authorized substances from a positive list are used.

*3 Positive List System

(Positive List System for Food Utensils, Containers and Packaging)

Established by the Ministry of Health, Labor and Welfare of Japan, this system outlines the specifications and standards for the use of food-contact utensils, containers, packaging etc., prohibiting the use of materials and methods that do not meet these standards.

■Contact

Public Relations, Harima Chemicals Group, Inc.

URL:https://www.harima.co.jp/en/inquiry.php