R&D Products

Paper Chemicals

Using water-based resin synthesis technologies, Harima develops a variety of paper chemicals: Polyacrylamide (PAM)-based paper strengthening agents for paperboard and rosin-based sizing agents that repel water and control water absorbency, as well as surface treatment additives that improve the printability and water repellency of paper and paperboard. We have diversified development of paper chemicals that cater to the Chinese and American markets that represent approx. 50% of paper production worldwide, in addition to Southeast Asia, a growing market for paperboard. We also promote pitch control agents that improve the productivity and operability of the pulp- making process, and barrier coating agents used in a multitude of paper applications employed in lieu of single-use plastics. These products promote efficient use of pulp and water resources, reduce waste and contribute to the mitigation of environmental issues. We accommodate market shifts from plastic to paper products through innovative development that contribute to the proliferation of paper products.

Indirect Food Additives

Certified by the World’s Leading Regulatory Bodies for Food Packaging Materials

Chemicals used in paper packages for food and drinks are called “indirect food additives” and require safety certifications for their possible effects on the users’ health. In line with these requirements, we promote development of products compliant with the world’s leading regulations such as the United States' FDA, Germany's BfR and China's GB9685. Our high molecular weight, amphoteric PAM-based paper strengthening agent "Harmide T2", and rosin-based sizing agents that contain synthetic anionic polymer emulsifiers, the “NeuRoz” series, announced in 2023 and 2017 respectively, are the first products in the world to comply with all three regulations as indirect food additives.

Water-based Coating Agents that Promote Use of Paper Products

In line with efforts to reduce plastic use, paper products are gaining popularity for their eco-friendliness and naturally decomposing cellulose materials. Paper products employed in lieu of single-use plastics are usually laminated with polyethylene (PE) films to provide similar functions, but the film poses significant problems in recyclability. Harima’s “Hicoat BC” series of water-based barrier coating agents replaces these laminate films while providing water and oil repellency as well as heat sealing. They are also certified by world regulations such as the United States’ FDA and Germany’s BfR for use as indirect food additives in packaging materials. In addition, we are also developing biomass-based coating agents.

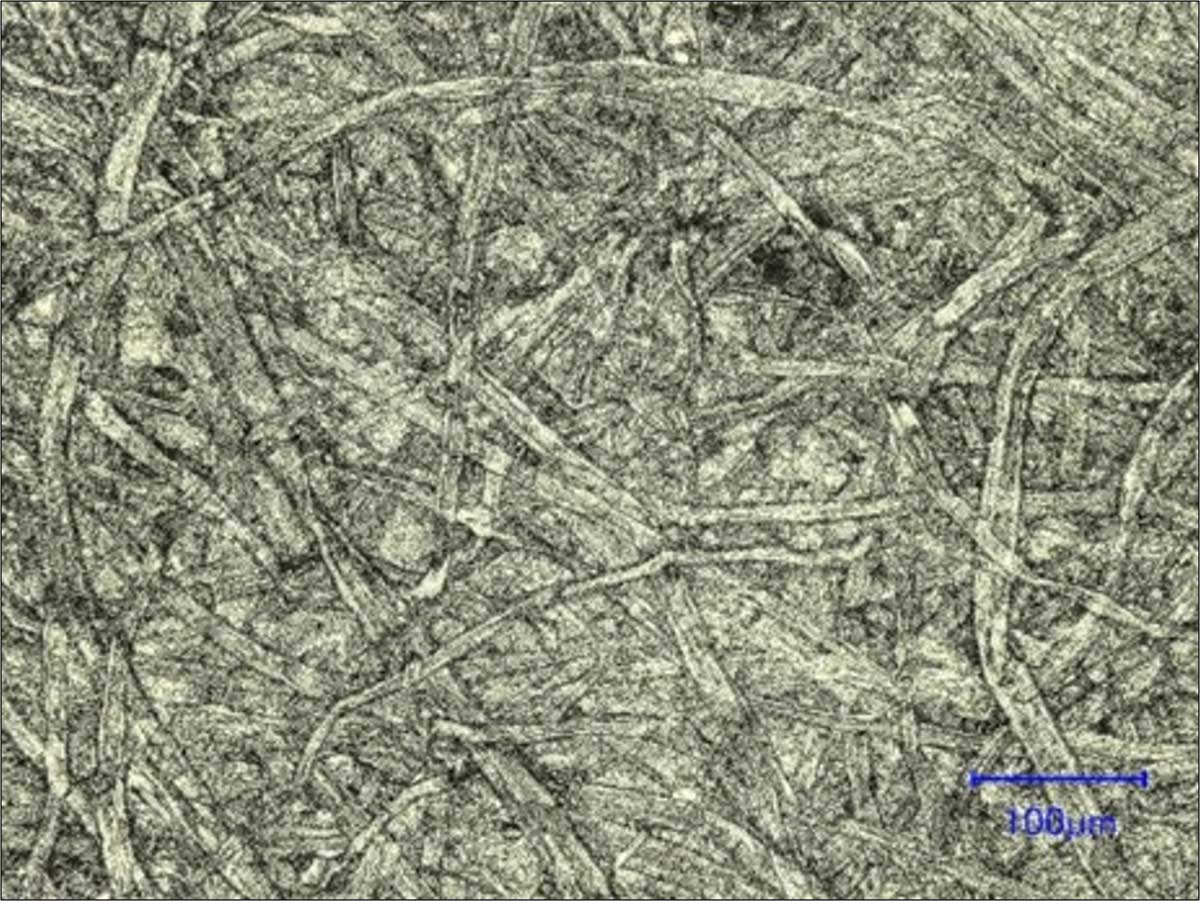

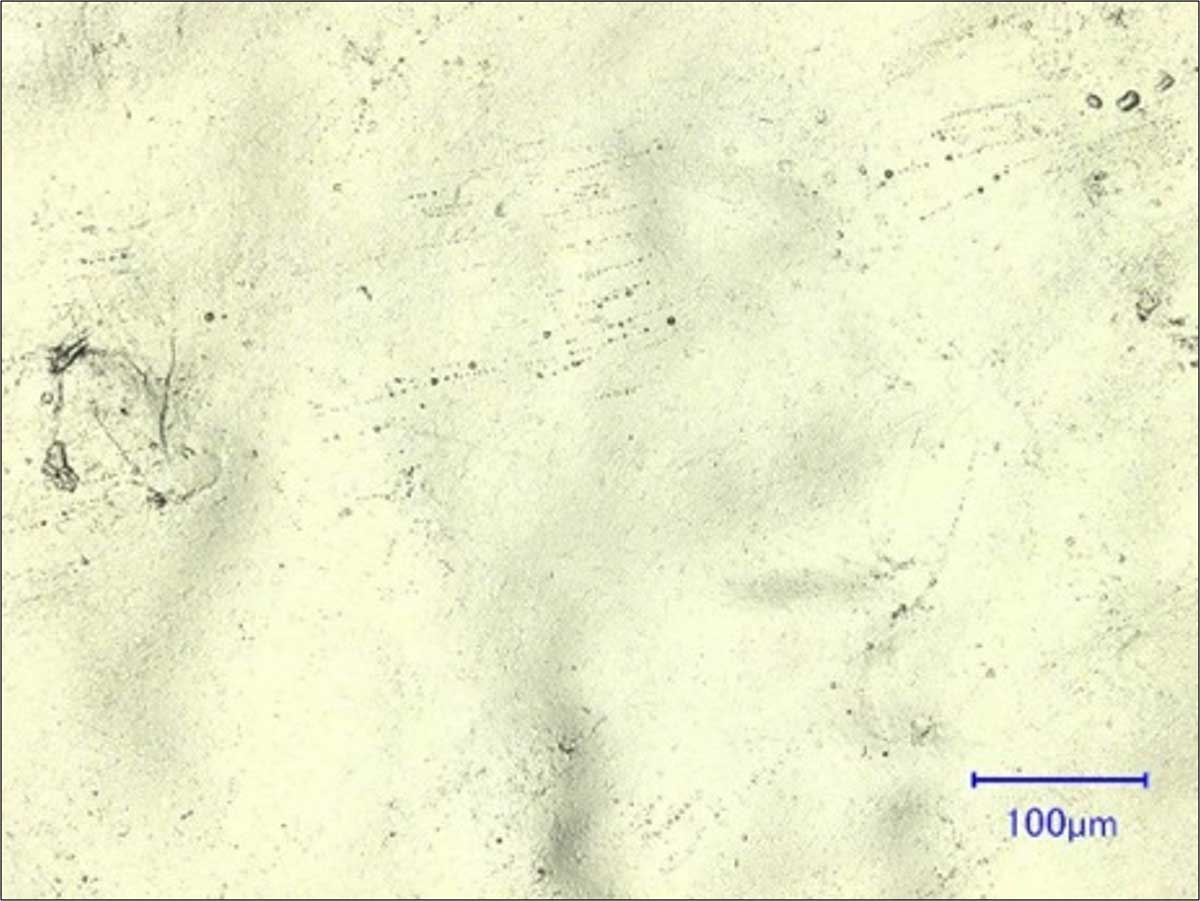

Closeup of paper surface without (left) and with (right) barrier coating

Process Improvement Agents (Pitch Control Agents)

Reduction of CO2 emissions and energy use is a pressing matter across all sectors, and our process improvement agents play a significant role in the papermaking industry by improving efficiency of manufacturing processes. Resin residue within pulp and synthetic resins from glues and adhesives stuck to used paper form clumps of deposit called “pitch”, which lowers the efficiency and quality of recycled paper. The “AS” series of PAM-based pitch control agents prevents pitch formation while minimizing resin adhesion, and is gaining international recognition for its effectiveness. We are expanding product portfolio for to cover used paper pulp as well.

Chemicals that Contribute to Environmental Conservation

(Retention Aids for Deinked Pulp)

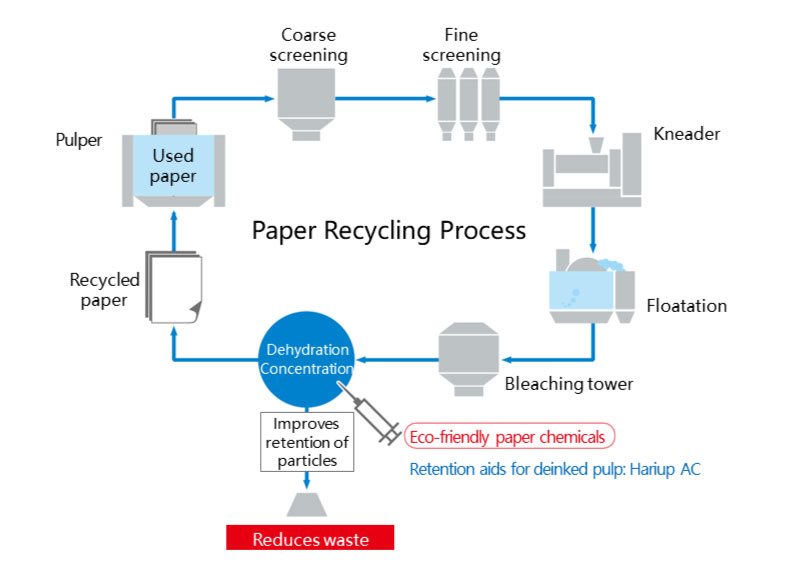

In addition to chemicals that enhance paper quality, Harima also manufactures chemicals that contribute to paper recycling and emission mitigation at paper mills. Inorganic materials such as calcium carbonate added during manufacturing to enhance paper quality, are extracted and treated as waste during the recycling process. The “Hariup AC” series of retention aids reduces the amount of waste produced during the deinking of pulp, thus contributing to enhancing recycling and sustainability of paper mill operations.